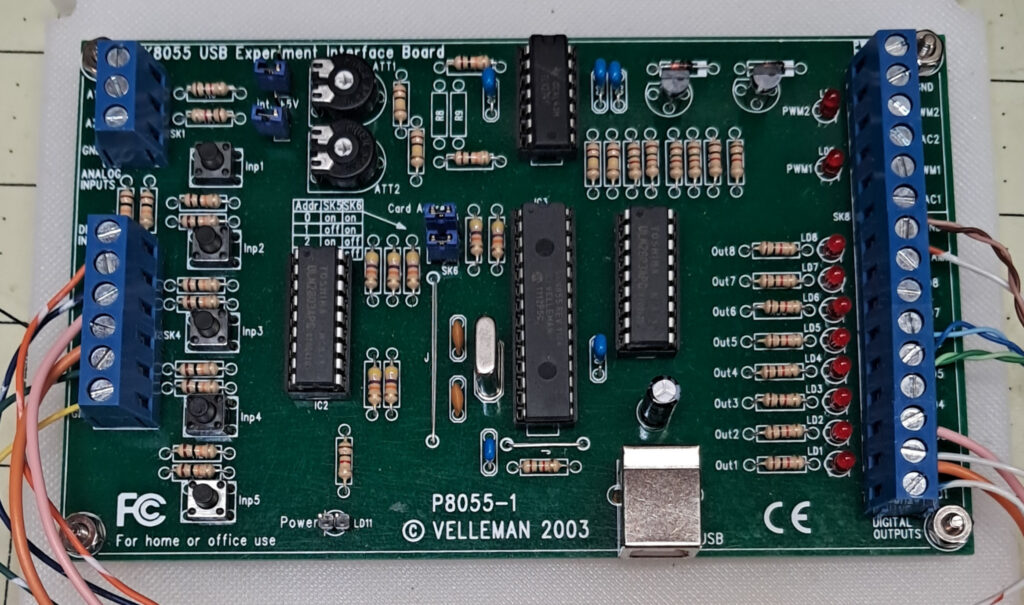

The USB controller that I’d like to use to interface the motor drive with the PC software is the venerable Velleman K8055, same as used with Lesvedome. It’s a good DIY solution that I’m already very familiar with. I’ve downloaded and installed the necessary K8055 Library files in Linux Mint so I can connect to it, and the only piece of the puzzle I’m missing is the INDI driver. I’ve never written and INDI driver, but I used to really enjoy programming, although that was literally decades ago, so it may take me a while to crack this nut. However, since I haven’t found any existing K8055 INDI drivers online so far, I guess I’ll have no choice but to learn how to do it myself.

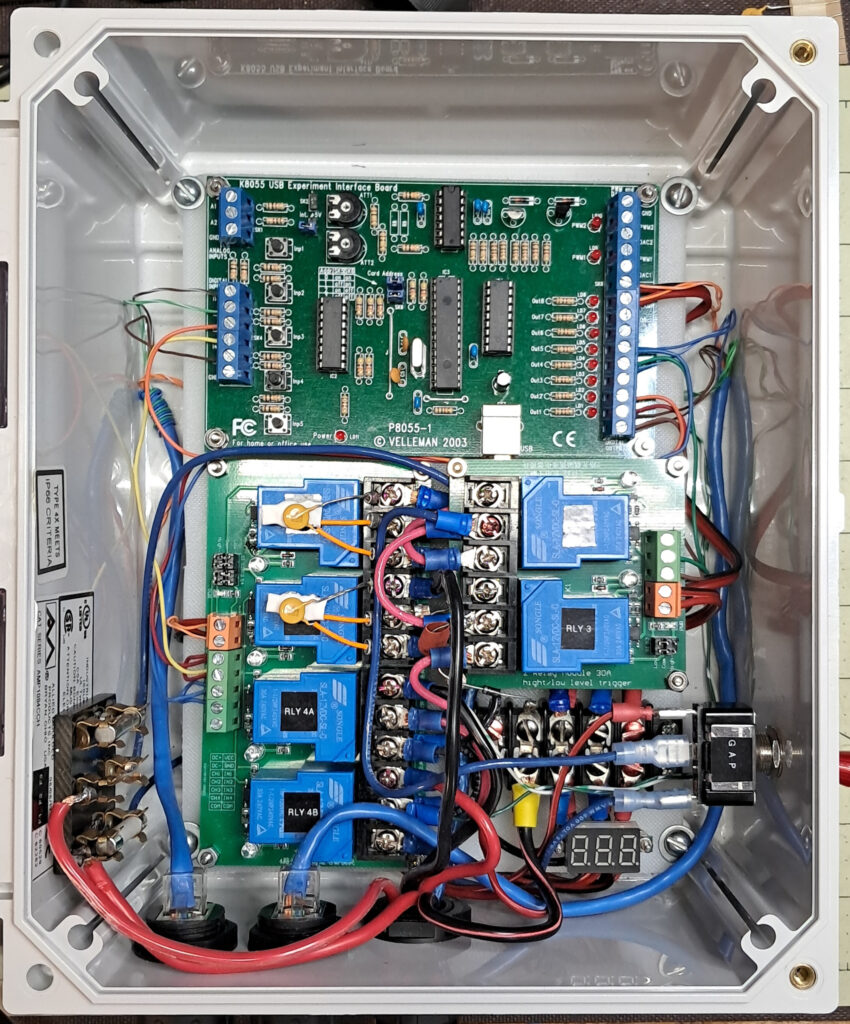

The motor controller is being built into a waterproof housing, except for two relays that will control the shutter motor and lower door actuators, which will need to be mounted separately up in the rotating dome. There will be a set of contacts at a fixed location that transfer power from the lower controller to the upper, plus a couple of inductive links to pass shutter/door open and closed feedback signals down to the controller card.

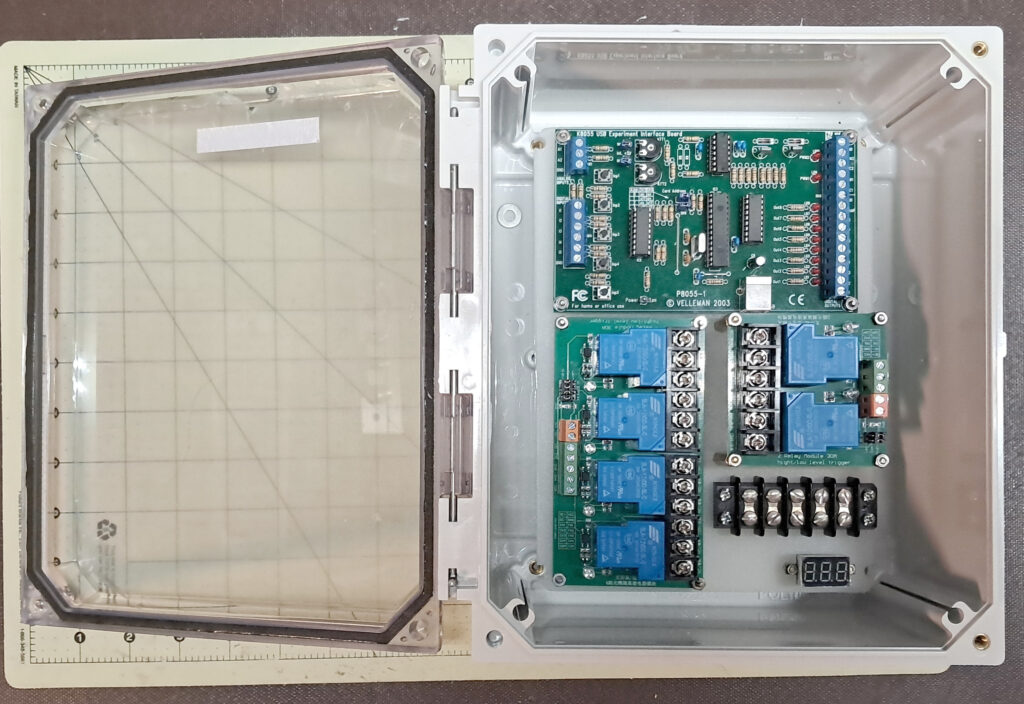

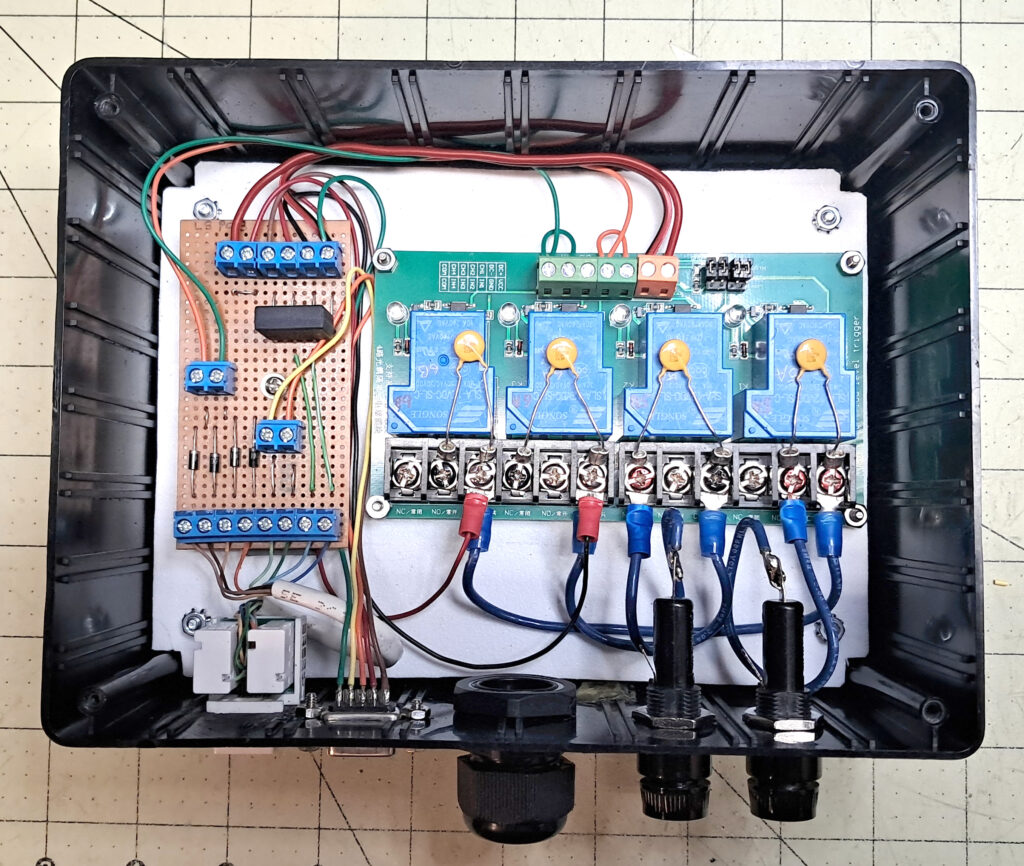

To make everything within the box, and still have access to the USB socket on the bottom edge of the Velleman card, the double relay module is mounted on standoffs to allow the USB cable to snake underneath and plug into the socket.

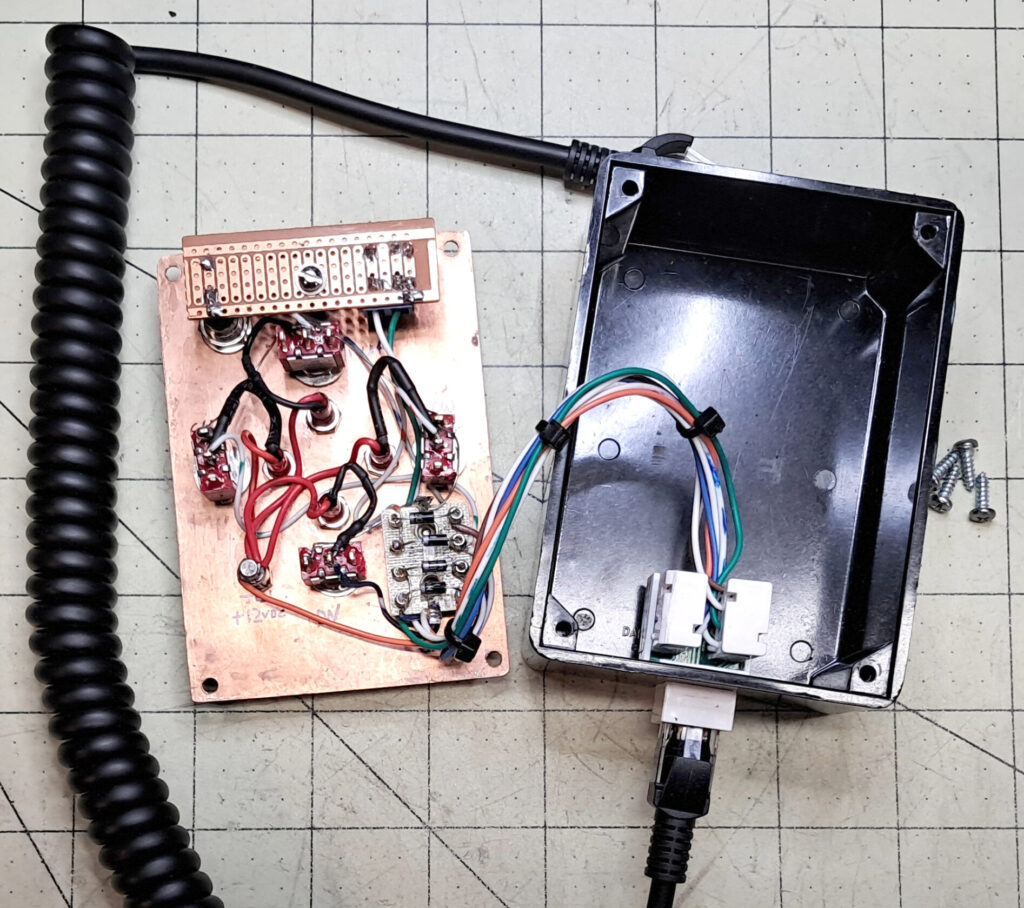

I still have the prototype controller I built for my Exploradome, but decided to do a more professional-looking build and at the same time simplify the original design by using relay modules that are readily available online. It was necessary to modify the original Lesvedome schematic somewhat to adapt it to the modules, but the end result is much simpler and neater than my prototype ever was.

One issue worth mentioning that I encountered with these relay modules is that I could not find any with 30-Amp double pole double throw (DPDT) relays. So instead, I used two single pole double throw (SPDT) modules with their input signal lines paralleled to emulate a DPDT relay. The six relays shown in the photo are set up to provide two SPDT and two DPDT relays.

A hand controller is also included in the design for ease of use. There are four control switches, two for controlling the dome’s azimuth motor, and two for opening and closing the shutter / lower door. The four red LEDs next to the switches provide visual feedback, even when the dome is under software control. The handset interfaces to the controller through an RJ-45 feedthrough jack on the bottom side of the controller box.

Inside the controller the circuit is fairly simple. Besides the four control switches and associated LEDs, it has another front panel mounted bi-color red/green LED on a small PCB with the dropping resistor plus a two-pin connector. This LED indicates whether the dome is in an open or close cycle, red for open and green for close. There’s also four logic diodes to the switches on another small terminal board.

The upper dome control box contains only two DPDT relays, plus a few other components for the diode logic, and for providing +12VDC to the four-relay module. As with the main controller, I used two pairs of SPDT relays, with their control signals paralleled, to emulate the DPDT relays.

I added two control signals that are not on the original Lesvedome schematic. One signal indicates the completion of the Open shutter cycle , while the second indicates the end of the Close cycle. These two signals are coming from limit switches, so they are physically generated by movement of the shutter and lower door. They are not just a software timeout function, although adding a timeout as a third layer of protection is probably a good idea.

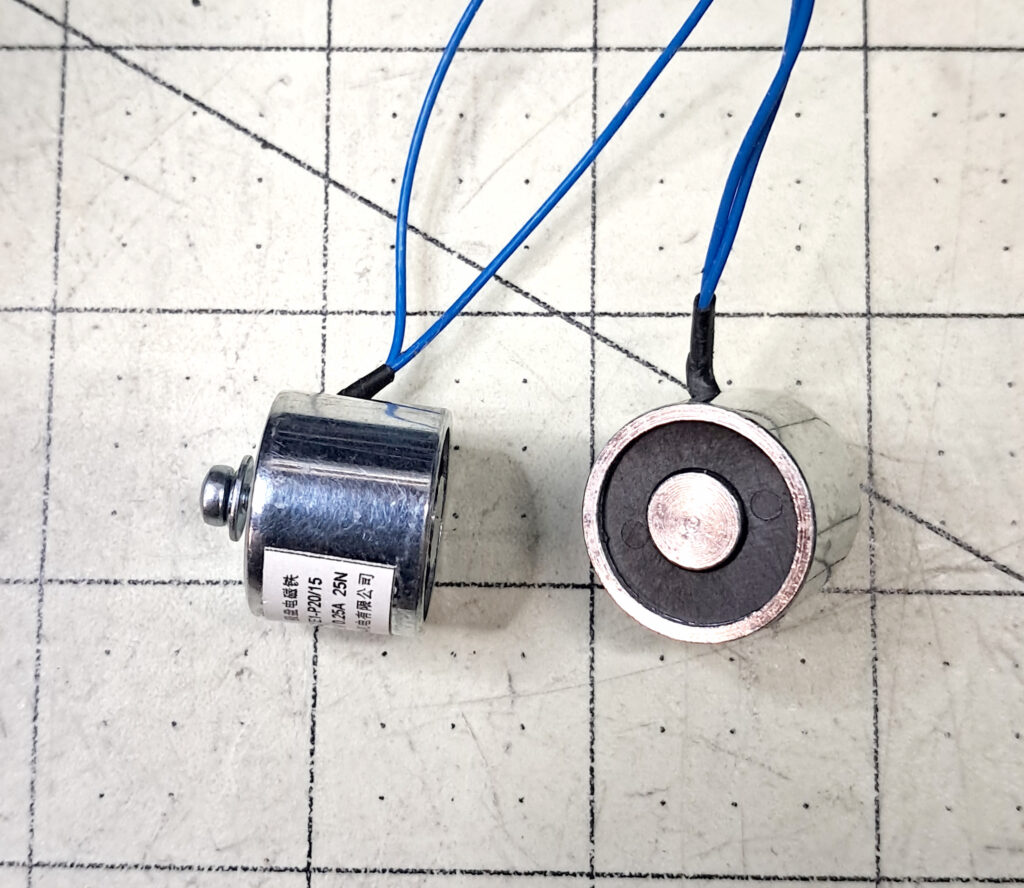

The open/close cycles only run while at the Dome’s Park position, and each of the two feedback signals activates a corresponding fixed electromagnet in the upper dome that lines up over a matching hall sensor connected to the main controller in the lower dome.

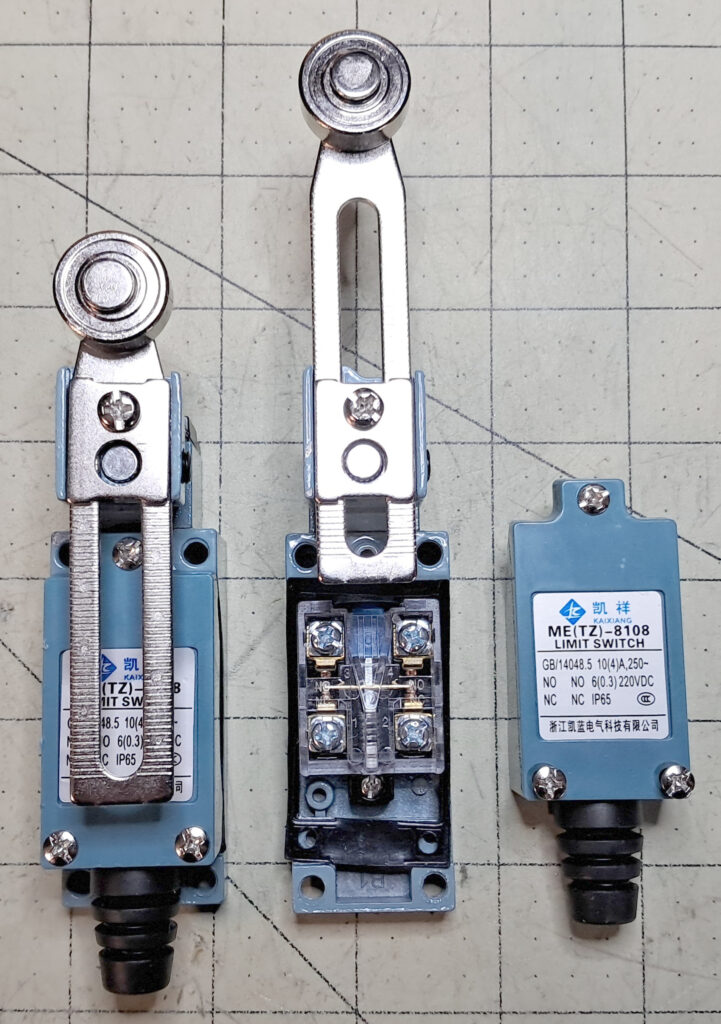

These are the types of limit switches I plan to use for the shutter and lower door. I prefer to use the lever arm switches wherever I can, but I have plunger switches, too, if needed. There will be one switch at the top and bottom of both shutter and door for controlling the open/close cycles, and are tied into the diode logic to the relay module inputs.

If something was to go wrong with a limit switch, there is a real possibility of damaging the dome or even possibly injuring someone, so I’m also incorporating emergency shutoff switches into the shutter controller as well. These will be another independent set of switches top and bottom for both shutter and door, to cut power to the motors in case of a limit switch failure that would try to drive either into their respective hard stops. These switches tie into the +12VDC power line to the relay module, cutting the power to the module if activated. So all-in-all I will have 8 limit switches.

These switches were listed as part number ME(TZ)-8108, and are made in China. I found listings online for three versions. The cheapest is listed as having a plastic roller and iron/copper contacts. The second has a metal roller and iron/silver contacts. And the third, which is the most expensive, is listed as having the metal roller plus copper/silver contacts. All the listings I found for this third version were out of stock, so I got the second tier, which was a buck or so more than the first. It’s easy to tell the difference in the rollers, but I don’t know how to tell if the contacts are really as stated.

It has one set of normally open (NO) contacts and one set of normally closed (NC), with no common between them. To make an SPDT switch, which is what I need, a jumper needs to be added from one NC contact to one NO contact. This jumper obviously becomes the common.

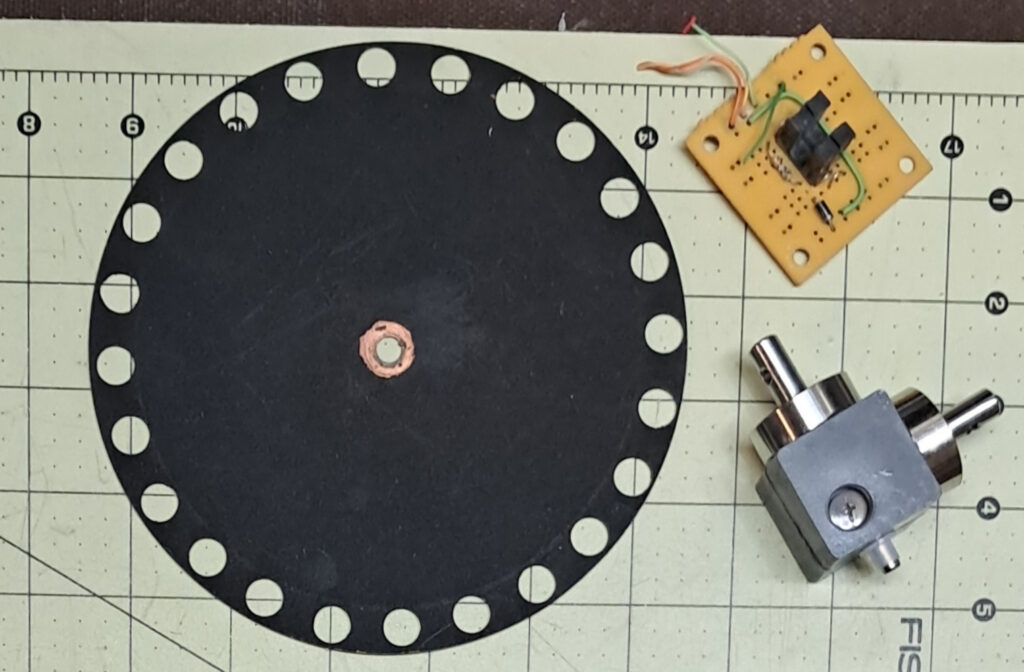

To complete the azimuth drive I need to assemble a gray coder for tracking the azimuth motor position. I pulled a couple of parts from the old Exploradome coder, and purchased a small right-angle gearbox. I still need to turn a couple of shaft adapters on my mini lathe to adapt the gearbox shafts to the encoder disc and motor, and then I need to make mounts for it and the photo sensors. The home sensor will also mount on the same assembly.

Page last updated 12/27/2025