Azimuth Drive

Back when I was using my Exploradome observatory I built a DIY motor drive setup controlled by a software program called Lesvedome. It worked well enough and I’d basically like to use a similar DIY solution with this new dome, except without the Lesvedome software itself, because it is a Windows-only program and I don’t use Windows anymore. I’ve been searching for a Linux-based software solution that will do the job, and thought I had found a couple of possibilities, but it now appears they were mostly talk and little was actually ever done. I’ll keep looking for ready-made software solutions, but at the same time I need to move ahead with building the new hardware.

The motor used for both the Azimuth and Shutter drives is a 12VDC gear motor originally designed for RV camper slide-outs. The online site I purchased these from states the amperage and output RPM varies depending on the torque supplied, and ranges from 12RPM @ 4-amps no load, to 6RPM @ 25 Amps with a max 850 in-lbs of torque. But according to a manufacturer spec sheet I found on another website, it appears that in “normal” operation they are meant to provide around 400 in-lbs of torque at about 9.5-amps. They also have an integrated brake with a holding torque of 500 in-lbs.

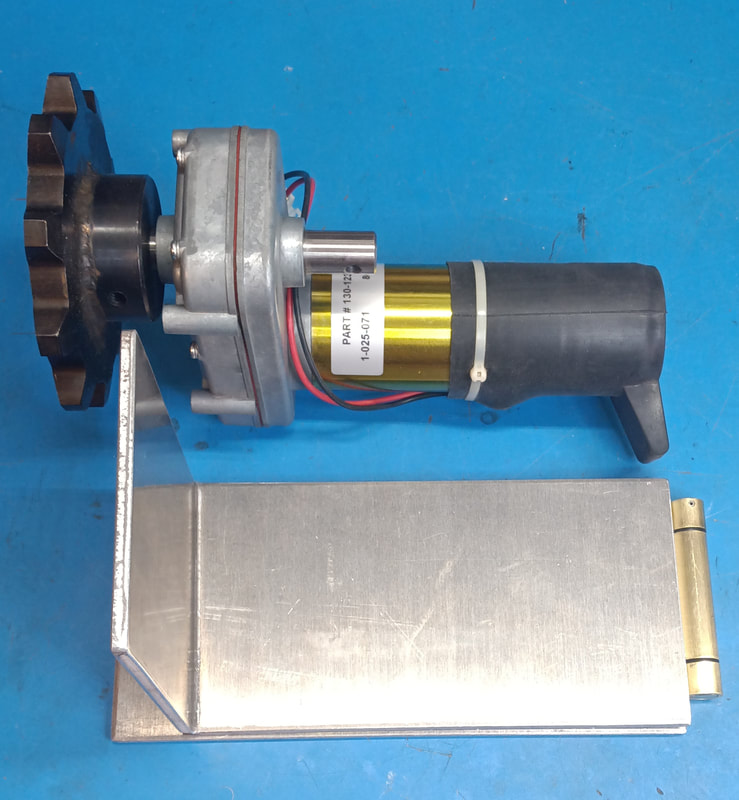

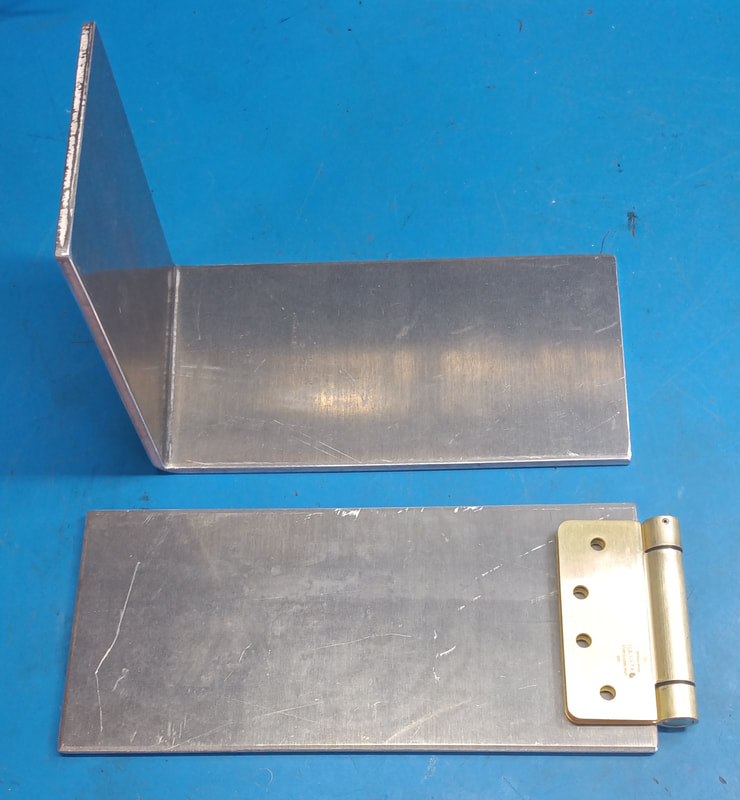

My first task was building the azimuth drive mount. The metal components for a simple motor mount were made by a local metal fabrication shop, but I will do all the drilling and assembling of the plates and motor. This is more or less the same type of hinged motor mount Ash uses, but is made specifically for this gear motor. The hinge shown is a commercial-grade door hinge, which is higher quality than typical cheap door hinges. I learned from my ExploraDome drive not to use a cheap hinge, because it rattled whenever the dome was in motion.

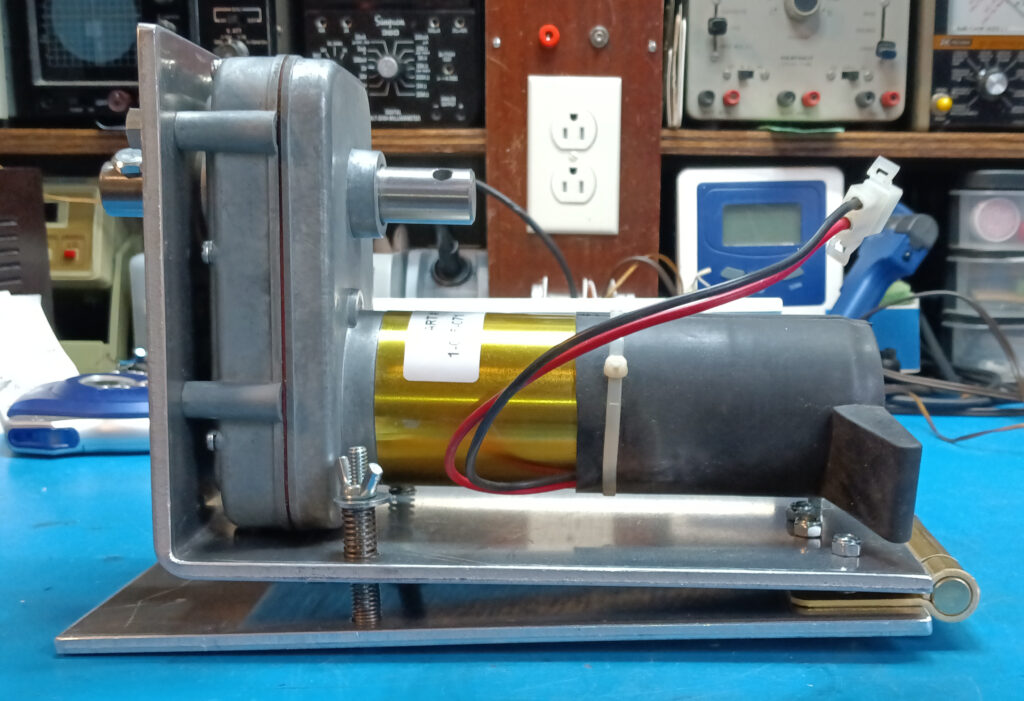

In this photo, drilling and assembling the mount is done, and the motor is bolted in place. The two hinged plates are spring loaded, and all that’s left to do is bolt the mount onto the dome ring, and install the drive sprocket on the front motor shaft. Once it’s manually rotating the dome I’ll make a gray coder to integrate it with the motor drive circuitry.

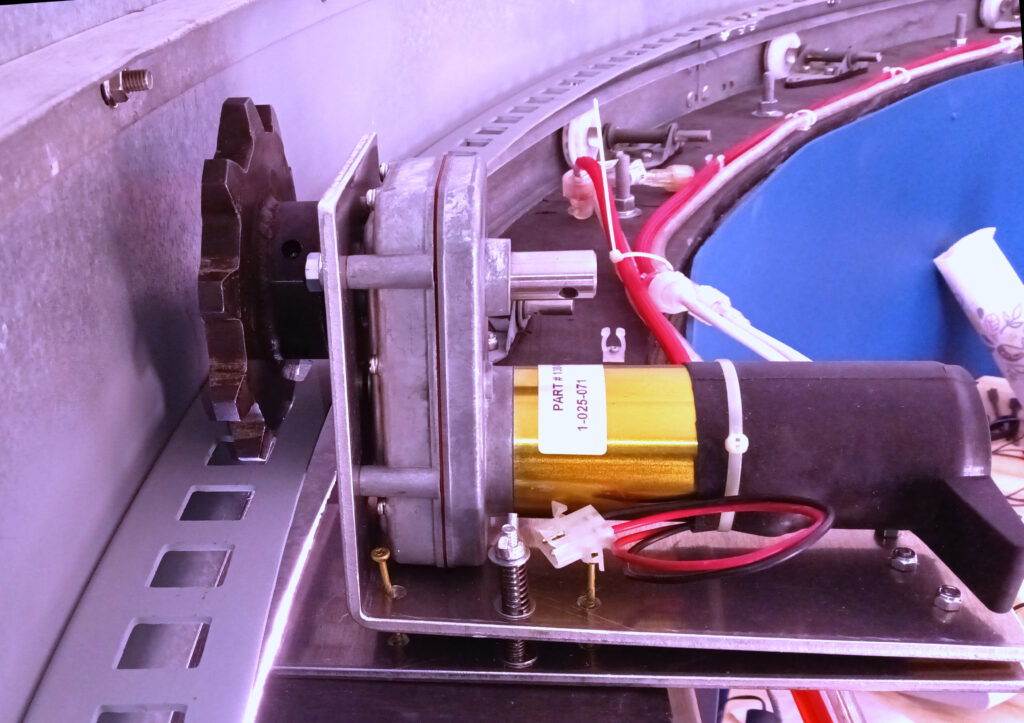

The azimuth motor drive is now installed, and for testing I used a 12-Volt 8-Amp gel cell as the power source, since the motor is only drawing about 5-amps in operation. The motor is performing very well and rotates the dome easily, with one full rotation taking 3-1/4 minutes (the circumference is 39-ft 3-in).

In the Ash manual I have, they use a right-angle gearbox on the azimuth drive, so that their big AC motor sits parallel with the dome, but because my DC motor already has a 163:1 gearbox attached, and is much smaller, it can sit perpendicular to the track without sticking out too far and being a hazard. The drive is fairly quiet as well, with just the hum of the motor plus some noise generated by the sprocket teeth on the gear track, but it’s at a level that I find completely acceptable.

Something else I have not found necessary so far is adding pulse-width modulation (PWM) for motor startups, to prevent the sprocket from slamming its teeth into the track on every move. The slow output speed of the gear ratio, plus the spring loading of the mount base, which allows it to flex a little, made it a non-issue. The springs also allow for a small amount of upward or downward movement if needed.

Shutter and Lower Door Drive

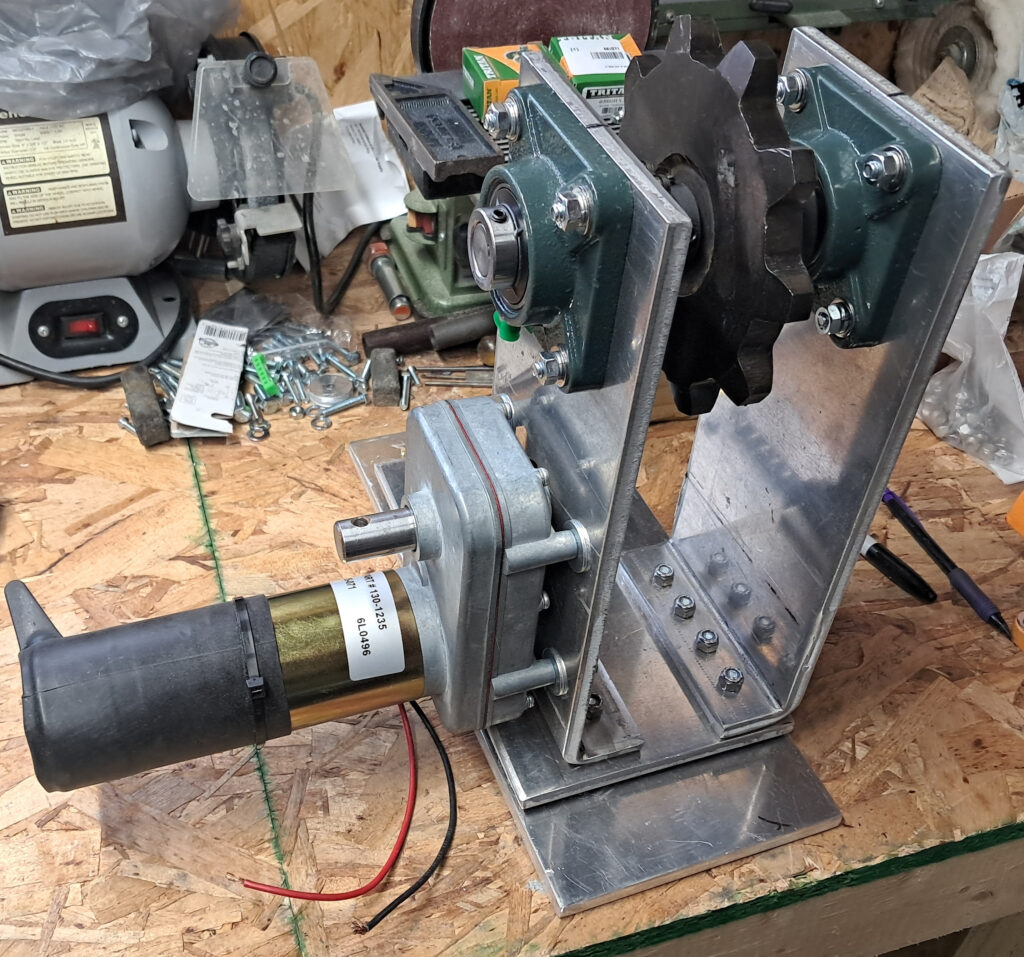

While the Azimuth drive was relatively simple to construct, the shutter drive is a bit more problematic. I couldn’t really wrap my head around what this drive was going to look like until I had completed the dome to the point of sliding the shutter frame in place on top. The Shutter motor and sprocket gear are identical to the azimuth, but I found the gap between the top of the dome and the shutter’s drive track is too wide for this small sprocket to work if it is installed directly onto the motor shaft. And I can’t use a larger sprocket because it would require too large a hole in the dome. So, I decided to again build a mount similar to what Ash shows in their manual. I’ll build this mount with a second shaft for the sprocket at the top, that will be driven by the motor mounted below through a chain drive. In the Ash manual it looks like they used some type of gearbox, but gearboxes can be quite expensive, so I went with the chain drive as a simpler, cheaper option. And it reduces weight.

The drive assembly is made from 3/8″ thick aluminum plate that was cut and bent at the same machine shop that made the azimuth drive plates. And once again I measured, drilled and assembled the drive myself. The upper shaft is 3/4″ in diameter, is keyed, and rotates in bearing blocks. The chain drive between the sprocket and motor is made with #41 chain and 10-tooth sprockets. It’s all still a work in progress until it gets tested under actually use, but it’s getting there. The shutter is too heavy to open and close by hand, so until this drive is up and running, I can’t move on to installing the actuators for the aperture door, because I can’t open it with the shutter closed.

Page last updated 12/27/2025